UASBR PLANT

The Up Flow Anaerobic Sludge Digestion treatment scheme is a highly efficient process for treating wastewater, particularly for the removal of organic content. Though complex, this method effectively reduces contaminants and improves water quality.

Wastewater from chemical-based industries is generally challenging to treat due to the presence of organic substances, inorganic salts, and organic solvents. These components contribute to high COD (Chemical Oxygen Demand), low BOD (Biochemical Oxygen Demand), and elevated salt concentrations, along with toxic inhibitory substances.

✔️ Biological treatment of wastewater with low to very high strength of wastewater.

✔️ Sewage treatment for medium to large towns/cities.

✔️ Treatment of distillery spent wash/pulp mill black liquor.

✔️ High organic wastes like slaughterhouses, poultry, large dairies, fish, and food industries, etc.

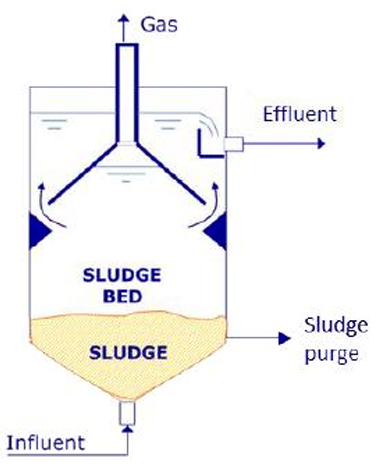

In this process, the influent is introduced at the bottom of the reactor and passes through a sludge blanket before exiting. This sludge blanket consists mainly of inorganic particles with anaerobic biomass grown around them, acting as a filter to remove suspended solids. COD reduction occurs through substrate breakdown by the biomass.

Unlike other processes, primary sedimentation is not required before UASB, as the inorganic particles themselves serve as media for sludge blanket formation. The treated wastewater is collected at the top of the reactor, ensuring effective purification. Additionally, biogas produced during the degradation process is collected at the top, making this treatment method not only efficient but also sustainable.

✔️ High capacity to treat slowly degradable subtracts at high concentration.

✔️ Very low sludge production.

✔️ Low energy requirements.

✔️ Possibility for energy recovery through methane combustion or Biogas Production.